As stated by a recent report from Mordor Intelligence, the UK is witnessing a steady growth in demand for HVAC equipment in the commercial sector. As more businesses invest in advanced heating, ventilation, and cooling systems, maintenance teams will need to spend more time on rooftops.

Working at height is one of the leading causes of workplace injuries, and rooftop HVAC access adds another layer of complexity due to personnel needing to navigate uneven surfaces, exposed skylights, limited space, and extreme weather conditions. Whether you’re overseeing a data centre, manufacturing facility, hospital, or commercial property, it’s your responsibility to ensure that your HVAC installers and technicians have the right level of fall protection in place.

In this guide, we’ll walk you through what to look for when choosing fall protection for HVAC work, and which systems provide the best protection for your team.

The risks of rooftop HVAC access

HVAC installers face a combination of hazards that make rooftop work particularly challenging. Uneven or fragile roof surfaces, harsh weather conditions, and restricted access zones can make it difficult to carry out the job safely. Add in all the tools, ducting, and electrical components, and you have a high-risk environment where even routine tasks can quickly become dangerous.

Without adequate fall protection in place, carrying out rooftop HVAC maintenance like filter changes or fan repairs could easily result in serious accidents or even death.

What to look for in fall protection for HVAC installers

Here are some important factors to consider when choosing fall protection for your HVAC setup:

1) Collective protection as your first line of defence

Always opt for collective fall protection such as guardrails or safety barriers where possible. They protect everyone working on the roof, without the need for individual PPE or harness systems. They also remove the risk of human error if personal fall arrest equipment is improperly fitted or worn.

Our permanent HVAC roof system guardrails provide continuous edge protection around plant equipment and access paths. They can be easily configured to suit different roof layouts, allowing your personnel to safely access multiple HVAC units without obstructing service routes or drainage systems.

2) Non-penetrating and low-maintenance options

The best systems protect both your people and your roof. Fall protection solutions with penetrating fixings can create weak points in the roof structure, leading to potential water ingress and corrosion. On the other hand, non-penetrating guardrails help to preserve the integrity of your roof and offer secure, stable protection for your workforce.

Our Katt Guard roof guardrails are non-penetrating and require little-to-no maintenance, making them the ideal choice for high-traffic rooftops that need to be accessed regularly. They’re made from high-strength aluminium which is naturally resistant to corrosion, so you don’t need to worry about forking out thousands on routine maintenance tasks.

3) Compatibility with your roof structure

Not all roofs are built the same, so your fall protection shouldn’t be either. Your roof guardrail system must integrate seamlessly with your roof type, whether it’s made from metal deck, single-ply membrane, or composite panel. This will ensure that the system continues to perform safely without compromising your roof’s drainage, insulation, or warranty.

Our modular roof guardrails are extremely versatile and suit a wide variety of mounting applications. They can be easily reconfigured as your plant equipment or layout changes, and you can combine them with our walkways, access stairs, and platforms to create a safe and reliable environment across your entire rooftop.

4) Proof of compliance and ongoing certification

Compliance is non-negotiable when it comes to fall protection. Always ensure that your fall protection systems meet the relevant safety standards (i.e. BS EN 13374:2013 for temporary systems, and BS EN ISO 14122-3:2016 for permanent guardrails, and The Work at Height Regulations 2005) for load, stability, and design. Purchase your system from a qualified provider to ensure that every component has been properly tested and documented.

Our roof guardrail systems all come with clear evidence of certification, so you can demonstrate your ongoing commitment to safety to clients and stakeholders. We can also complete inspections and issue you with re-certification to ensure that your system is continuing to perform as intended, even years after installation.

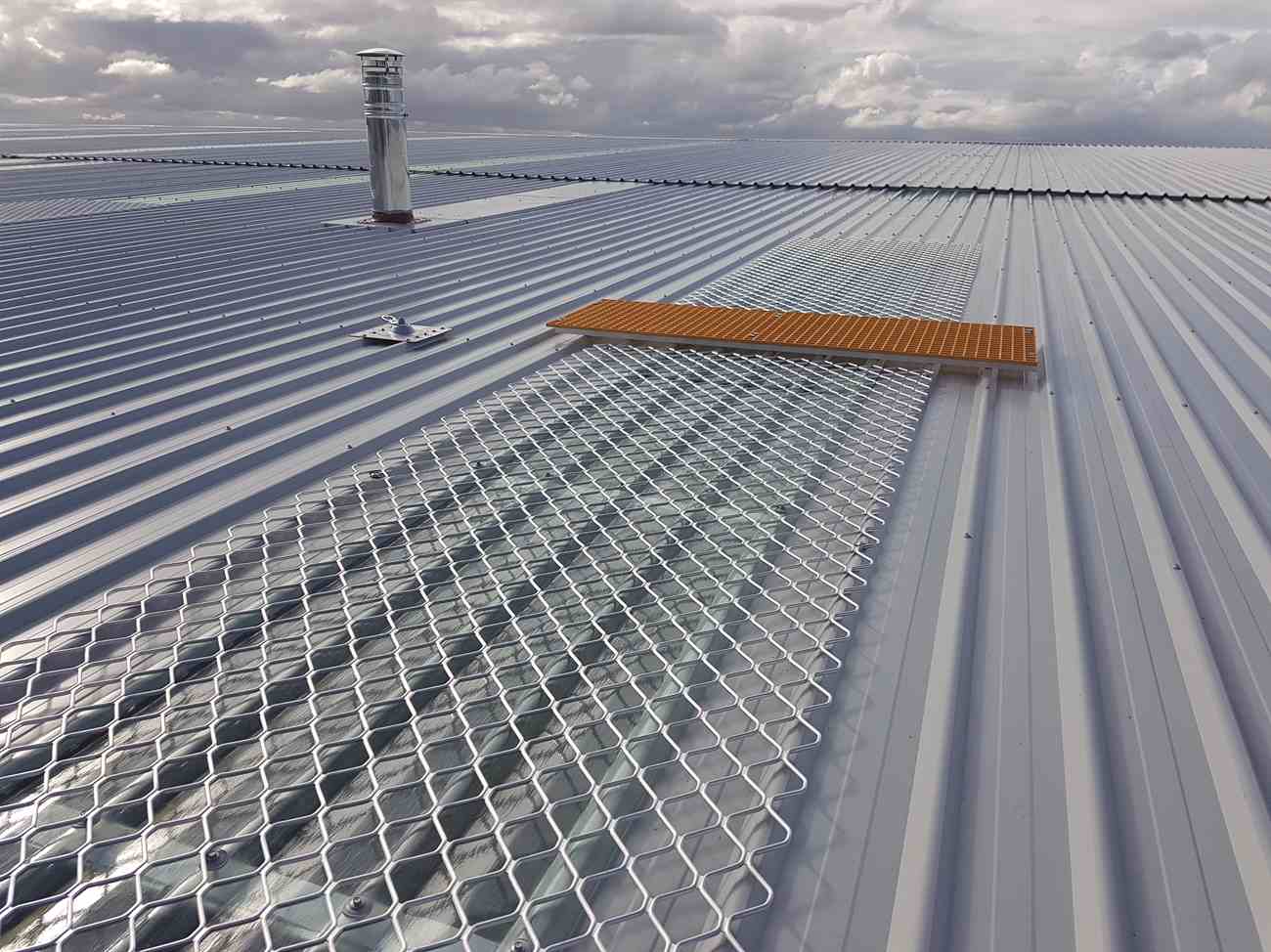

5) Don’t forget about skylight covers

Skylights are one of the most common, and often underestimated, fall hazards near rooftop HVAC zones. Fragile materials can easily give way under a person’s weight, even if the surface appears solid.

Our Katt Climb skylight covers provide a critical layer of protection, helping to prevent falls through fragile panels without blocking the natural light. They also serve as a visual safety cue by clearly marking potential rooftop hazards, ensuring that your personnel remain within safe zones while carrying out their routine maintenance tasks.

Protecting your people, one rooftop unit at a time

At Katt Safety, we work closely with facility managers, contractors, and safety professionals to design bespoke rooftop HVAC access solutions that integrate seamlessly across existing infrastructure. Our fall protection solutions are exceptionally strong and durable, providing maximum protection for your people with minimal disruption to your operations.

So, are you ready to improve your HVAC maintenance safety? Get in touch to discuss your project requirements and we’ll help you design the perfect fall protection solution for your facility.

FAQs

1) What type of fall protection is best for rooftop HVAC maintenance?

Collective edge protection systems, such as guardrails and safety barriers, are the most effective and compliant solutions for routine HVAC access. They protect your workers at all times, whilst reducing your training and equipment costs over the long term.

2) How often should rooftop safety systems be inspected?

Rooftop safety systems should be inspected annually, or more frequently if the system is exposed to harsh environmental conditions or heavy use. Regular inspections help identify signs of wear or damage, ensuring your system continues to perform reliably and remains fully compliant.

3) Do I need skylight covers if guardrails are already in place?

Yes. Skylight covers protect against falls through the roof surface, whereas guardrails protect against falls over the edge. Both solutions are essential for safeguarding your team, no matter where they’re working on the roof.